Descrizione di prodotto

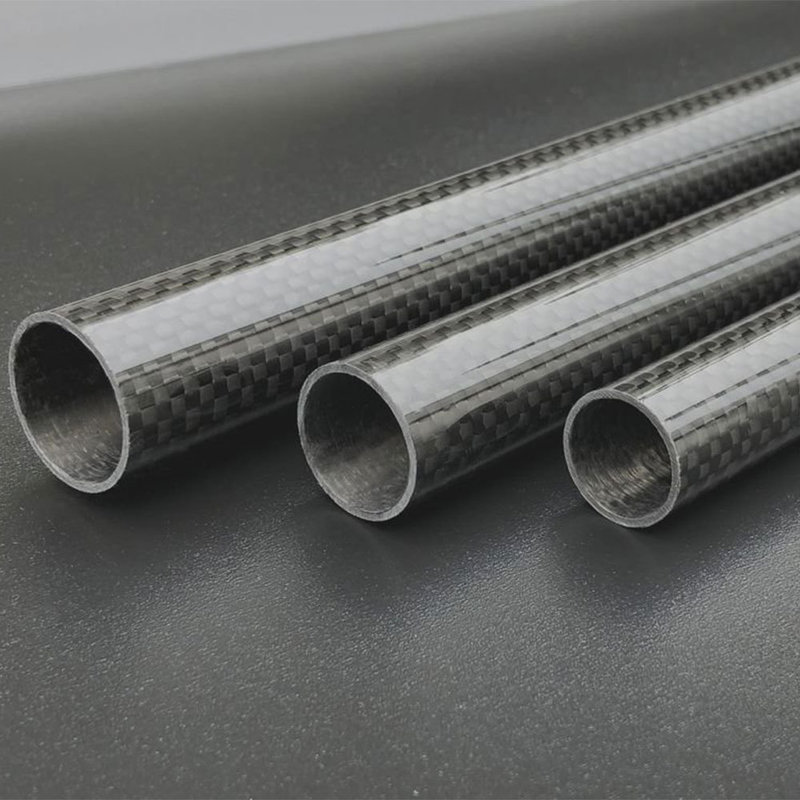

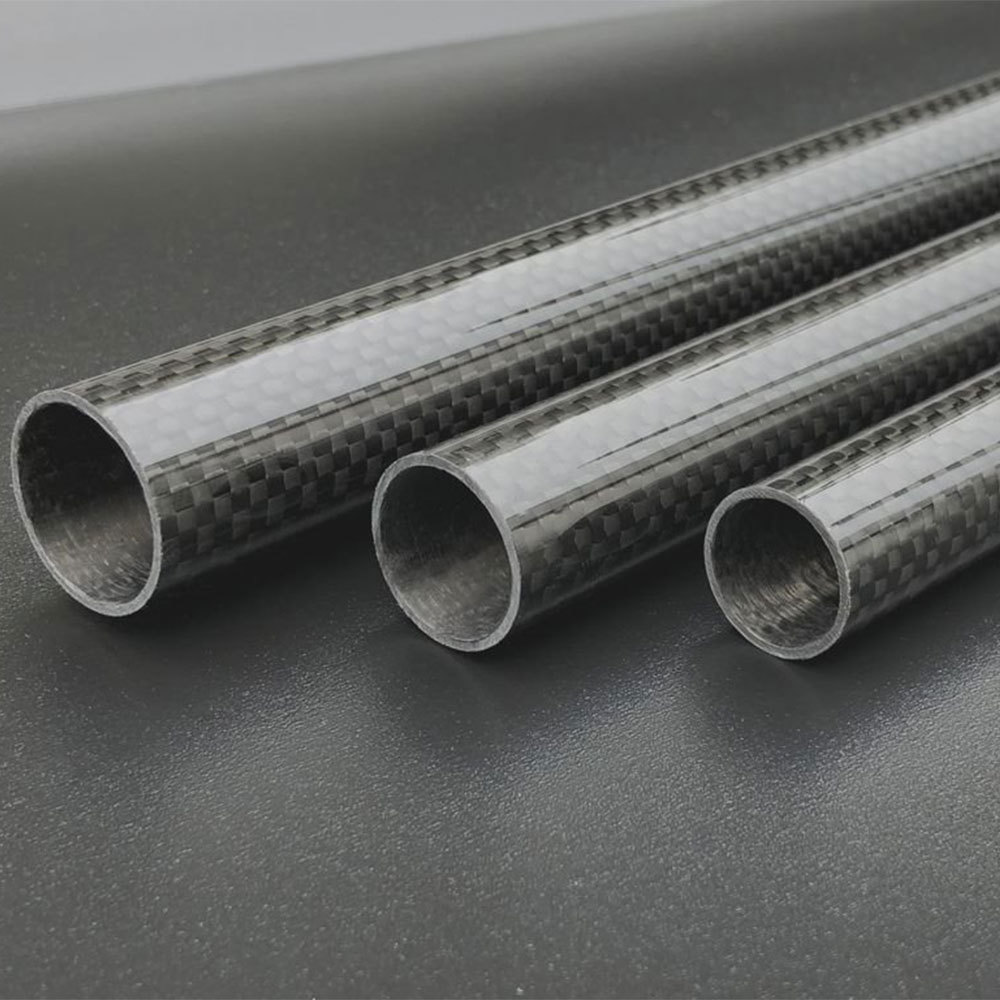

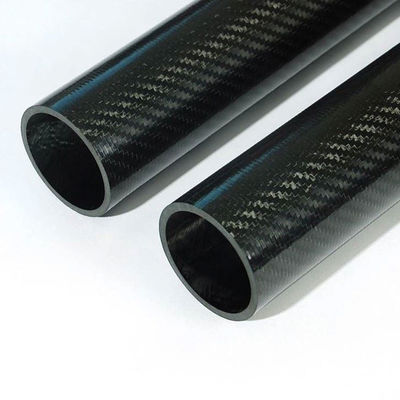

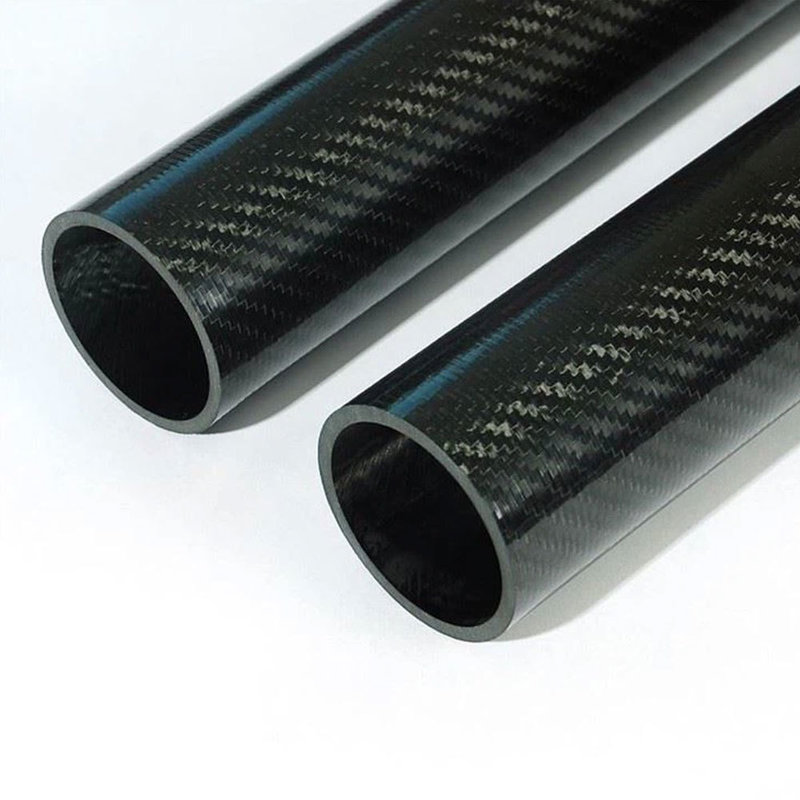

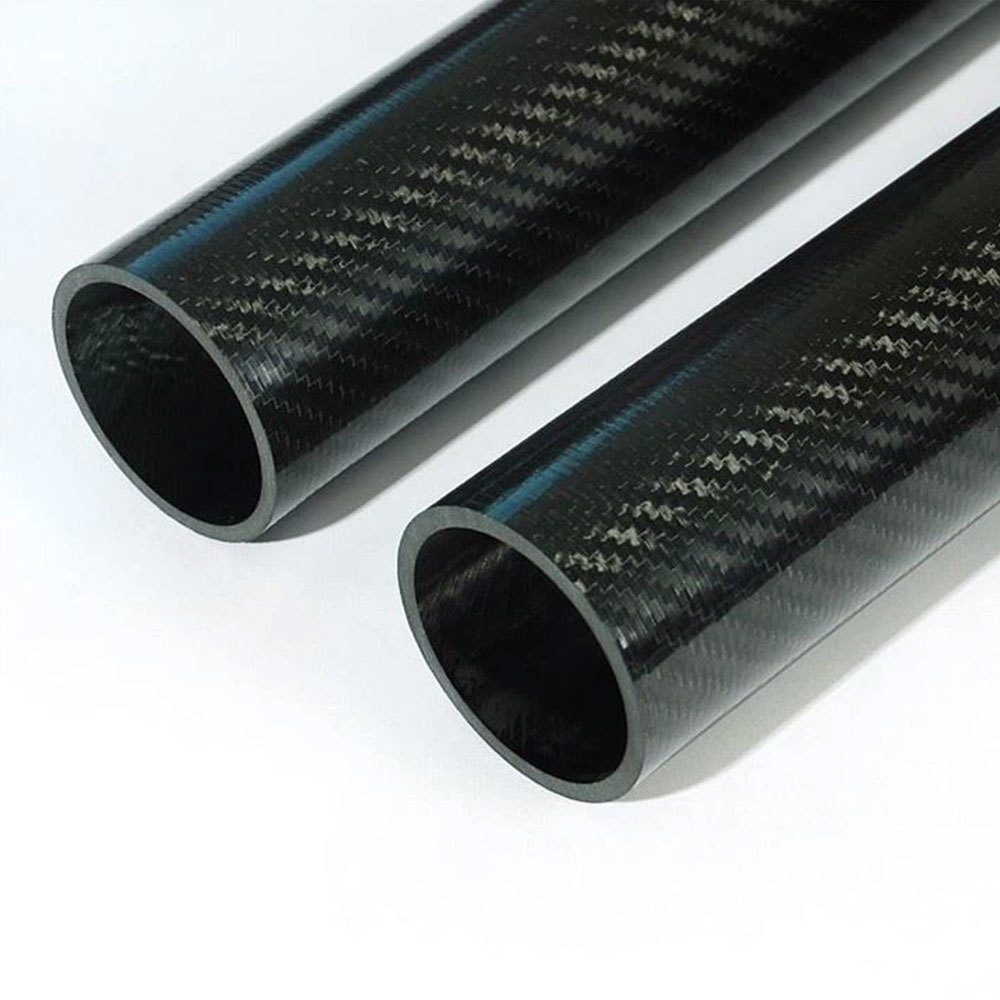

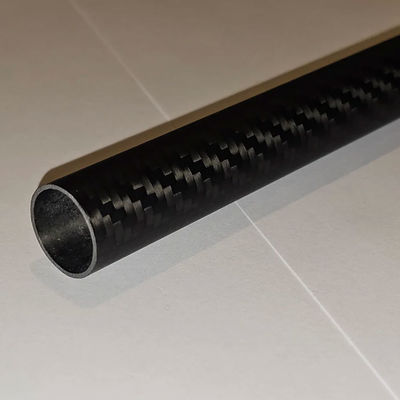

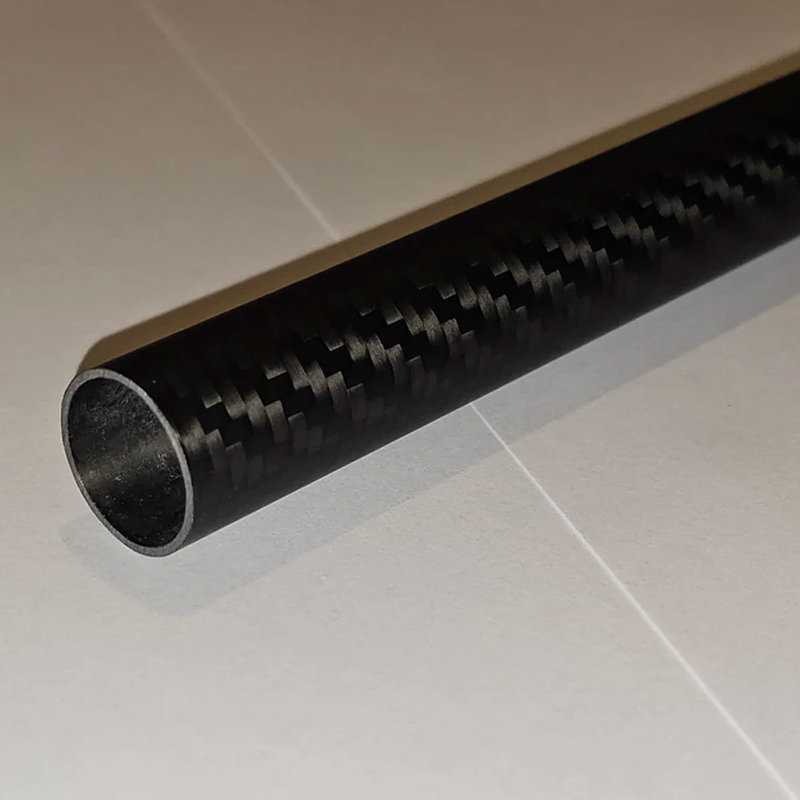

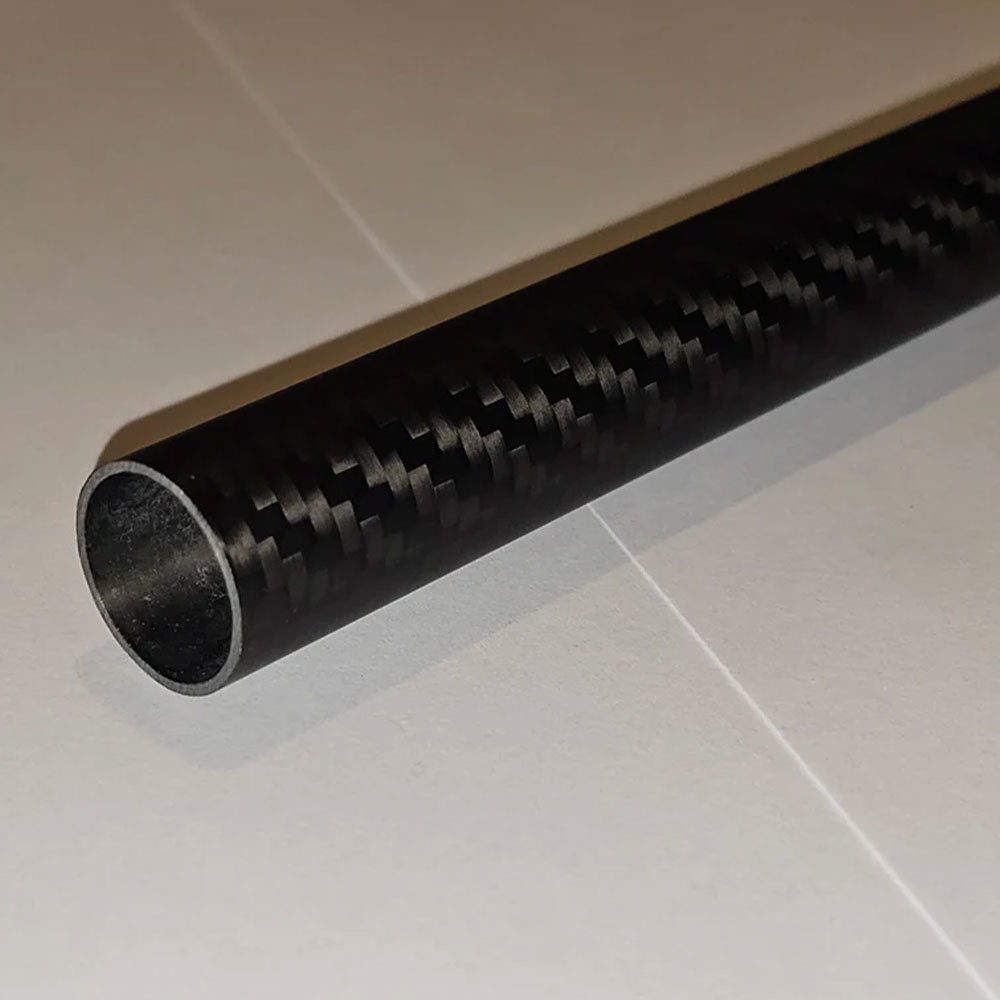

Roll Wrapped Carbon Fiber Tube Twill Weave Gloss Finish - Industrial Carbon Fiber Tube

Industrial carbon fiber tubes are high-strength, lightweight cylindrical structures made from carbon fiber reinforced polymer (CFRP). They are designed for demanding industrial applications where rigidity, corrosion resistance, and low weight are critical. These tubes are widely used across aerospace, robotics, automation, defense, and other heavy-duty industries.

This Roll Wrapped Carbon Fiber Tube uses high strength unidirectional T-700 equivalent carbon fiber core with an epoxy resin system to ensure a strong rigid tube that will meet your needs. In addition to this high strength uni core this tube is finished with a beautiful 2×2 twill weave carbon fiber and then given a gloss finish. Due to raw material constraints it is hard to create pipes exactly at a specific measurement unless they are built over-sized and machined down so that is why our pipes may be a few thousandths off from our ideal measurement we are trying to match.

Thanks to our industrial manufacturing processes (including Pultrusion, Pullwinding or K1 technologies) and extensive experience in composite materials, Epsilon designs and manufactures lightweight composite tubes and profiles in all shapes (round, oval, square, rectangle, or special shapes) using materials tailored to your needs:

Epoxy matrix (or other specific resins, as required),Carbon fiber adapted to mechanical stresses: High Strength (HS), Intermediate Modulus (IM), High Modulus (HM) or Very High Modulus (UHM),Natural fibers (flax, basalt,…),Synthetic fibers,Function integration (such as fiberglass or thermoplasic insulating/protective layer), Finishing (machining, assembly, non-destructive testing…).

Key Features

- High Strength-to-Weight Ratio: Stronger than many metals yet significantly lighter.

- Corrosion Resistant: Resistant to chemicals, moisture, and environmental degradation.

- Thermal Stability: Maintains performance across a wide range of temperatures.

- Precision Engineering: Can be manufactured to tight tolerances for industrial machinery and equipment.

- Versatile Finishes: Available in matte, glossy, or customized coatings depending on application.

Applications

- Robotic arms and automation equipment

- Industrial machinery components

- Aerospace and aviation structural parts

- High-performance tooling and fixtures

- Lightweight shafts and rollers

Manufacturing Methods

- Pultrusion: Continuous production of consistent-diameter tubes for structural applications.

- Filament Winding: Allows complex shapes and variable wall thicknesses for high-strength requirements.

- Roll Wrapped / Laminated: Ideal for heavy-duty or precision applications requiring customized fiber orientations.

| Material |

Carbon Fiber Round Tube |

| Shape |

Round/Oval |

| Technology |

Roll-wrapped or pultrusion |

| Dimension |

The existing inner diameter of the mold is 4mm-50mm with a length of 1m. |

| Customizable size: The maximum diameter can be 200mm, the longest can be 3m. |

| Surface |

Black glossy/matte surface/painted |

| Glossy 3k weave/matte 3k weave |

| Color metal wire weave |

| Feature |

lightweight, high-strength |

| Working Temperature |

Usually, -30-120 degrees, if special requirement, please let us know. |

| Place Of Origin |

China |

| Function |

Marine, Agriculture Tools, Arrow Shaft, Medical, Sport Products |

| Tolerance |

Diameter Tolerance: +/-0.1mm |

| Length Tolerance |

+/-1mm |

What are Carbon Fiber Tubes?

Definition and Basic Characteristics

Carbon fiber tubes (also known as carbon fiber rods if they are stiffer and heavier) are predominantly cylindrical structures made from carbon fibers implanted in a polymer matrix, oftentimes an epoxy resin. They are however also available in other shapes such as rectangular or hexagonal, to suit different structural and design requirements. The CFRP tubes distinguish themselves in the market due to the high strength-to-weight ratio; they have more strength and are much lighter compared to their basic counterparts - like steel and aluminum. The carbon fibers provide high tensile strength, usually on the order of 3.5 GPa (Gigapascals), while the polymer matrix binds them together and provides some rigidity to the fibers for strengthening. Carbon fiber tubes also have a density of about 1.6 g/cm³ compared to steel at 7.8 g/cm³ and aluminum at 2.7 g/cm³.

Comparison with Other Materials

Carbon fiber tubes differ considerably compared to other materials. For instance, compared to steel and aluminum, carbon fiber tubes weigh approximately 70% and 40% less respectively, while having equivalent or better strength—application-related increased efficiency and performance, as seen in industries such as aerospace and automotive. In addition to this, carbon fiber tubes don't corrode like steel rusts over time or aluminum corrodes when the conditions dictate so. The modulus of elasticity for carbon fiber is about 230 GPa as compared to 200 GPa in steel and 69 GPa in aluminum, thus it shows that the CFRP tubes are stiffer and have less tendency to deform.

As for their thermal properties, Carbon fiber tubes again outperform traditional materials in terms of their thermal properties. Carbon fiber has a lower coefficient of thermal expansion (CTE) compared to steel and aluminum; that is, it expands and contracts less when subjected to variations in temperature. This dimension stability is highly demanded in applications where precision is a central requirement, as in aerospace and sporting equipment of high performance. Besides, carbon fiber's thermal conductivity is lower than metals, which makes it an excellent choice for applications requiring thermal insulation.

Besides that, any carbon fiber tube has greater fatigue resistance compared with its metal equivalents. Metallic materials, especially steel, and aluminum, upon experiencing cycles of load application and removal, tend to form micro-cracks, which will eventually lead to failure. Carbon fiber will maintain its integrity for a longer period under cyclic loading, a benefit particularly in aircraft structure applications and automotive parts where long-term durability is essential.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!